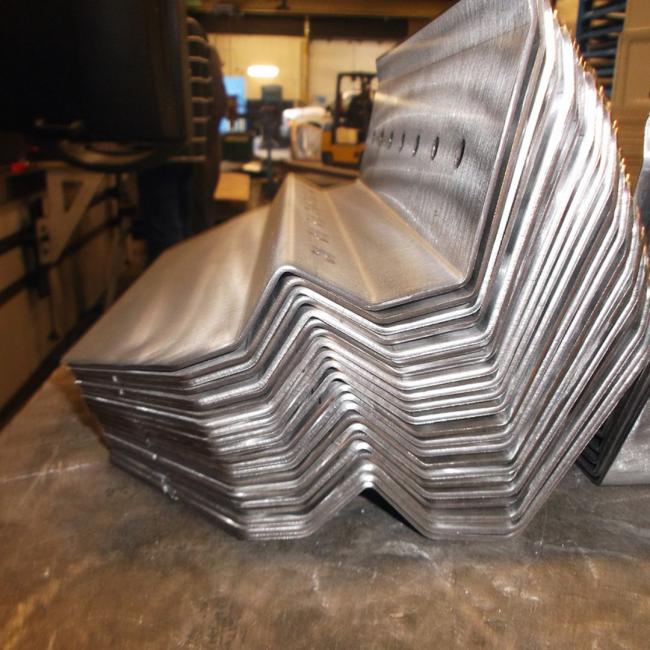

Precision Cutting and Welding Impact Stainless Steel Fabrication

In the world of stainless steel fabrication, precision is of paramount importance. Whether it’s applied to architectural projects, machine components, or other industrial equipment, the final product will perform optimally depending on the accuracy of the cutting and welding processes. The smallest error can compromise the integrity of the material or weaken joints, requiring costly reworking. Expert craftsmanship is not negotiable.

We at Baseline Custom Fabricating Ltd understand that stainless steel is a material that demands advanced tools, deep knowledge, and attention to detail. We are committed to delivering quality results for clients across the GTA and Ontario.

Why is precision cutting so crucial?

Accurate cutting plays a critical role in any stainless steel fabrication project. Precision cutting offers:

- Clean, consistent edges, minimizing finishing

- Better fits and easy assembly for welded parts

- Reduced waste, of both time and material, resulting in reduced costs.

- Material durability and resistance to corrosion

How Does Expert Welding Improve Final Fabrication Quality?

Welding stainless steel can be challenging due to its sensitivity to heat. Without skilled technique, the metal can deform, crack, or lose its protective surface. Precision welding helps ensure:

- Durable joints for demanding conditions

- Clean and visually appealing finishes

- Reduced distortion

- Reliable performance

Processes such as TIG and MIG welding are commonly used to deliver greater accuracy for light and heavy stainless steel fabrication applications.

What are some of the high-tech advancements in precision cutting?

Modern advancements, such as laser cutting, plasma cutting, and waterjet cutting, allow for complex shapes, tighter tolerances, and much greater consistency—an essential advantage for industries like construction and manufacturing.

How does it impact the quality of stainless steel fabrication?

With precision cutting and welding, stainless steel fabrication results in:

- Product longevity

- Better performance, even under demanding conditions

- Improved quality control

- Customer satisfaction

Simply, precision cutting is the backbone of quality stainless steel fabrication.

Why you should work with us

At Baseline Custom Fabricating Ltd., we have over 30 years of experience in providing high-quality stainless steel fabrication. With advanced equipment and specialized expertise, we are committed to exceptional quality and customer service. Call (905) 434-2556 and request a quote for your project today!

FAQs

What factors affect precision in stainless steel cutting?

Material thickness, cutting method, and machine accuracy determine how clean and consistent the final cut will be.

Why is expert welding important in stainless steel fabrication?

Skilled welding prevents distortion, cracks, and weak joints, ensuring the finished product remains durable and reliable.

Who offers the best stainless steel fabrication services in Toronto, Durham, and the GTA?

Baseline Custom Fabricating Ltd. in Courtice, Ontario, delivers top-quality fabrication backed by advanced equipment and 30+ years of industry experience.