How Laser Cutting Improves Precision in Custom Metal Fabrication

Laser cutting in Toronto is one of the cornerstones of metal fabricating in Ontario, offering unmatched accuracy, consistency, and efficiency. For projects that require tight tolerances and clean finishes, laser cutting enables fabricators to produce high-quality components while minimizing waste and reducing production time.

What Is Laser Cutting in Metal Fabrication?

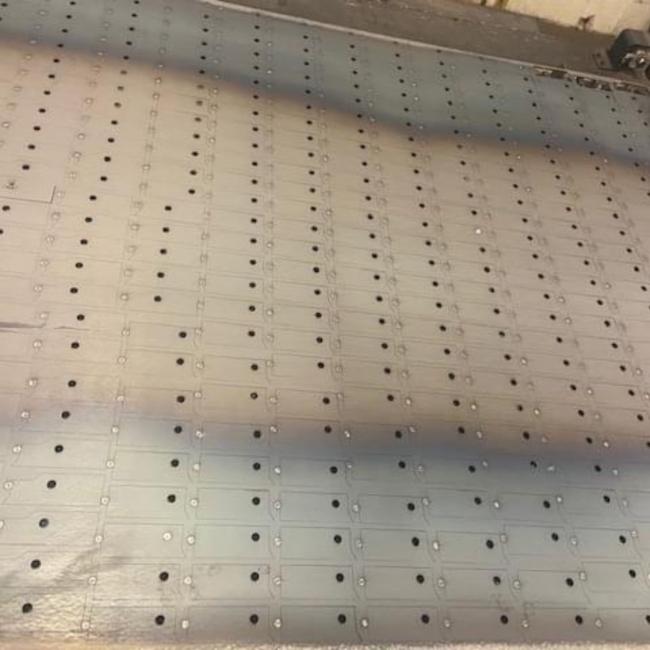

Laser cutting is a thermal cutting process that uses a focused beam of light to cut through metal with extreme precision. The laser melts or vaporizes the material, creating smooth edges and intricate shapes that are difficult to achieve with traditional cutting methods. This process is especially effective for stainless steel, aluminum, and other metals commonly used in custom fabrication projects.

Why Is Laser Cutting Known for High Precision?

One of the main advantages of laser cutting in Toronto is its ability to achieve consistent, repeatable results. Computer-controlled systems ensure accurate cuts every time, even for complex designs or fine details.

Because the heat-affected zone is minimal, laser cutting minimizes material distortion, allowing parts to maintain their intended shape and dimensional accuracy.

How Does Laser Cutting Improve Efficiency?

Laser cutting significantly reduces setup time and speeds up production. Designs can be quickly adjusted and executed without the need for specialized tooling, making it ideal for both prototyping and high-volume fabrication.

This efficiency translates into shorter lead times and lower production costs for custom metal components.

Where Is Laser Cutting Most Commonly Used?

Laser cutting in Toronto is widely used in industries such as construction, manufacturing, automotive, and architectural metalwork. It is ideal for components that require precision cutouts, detailed patterns, or clean edges ready for welding or assembly.

Why Choose Baseline Custom Fabricating Ltd. for Laser Cutting?

With a focus on quality, precision, and customer satisfaction, Baseline Custom Fabricating Ltd. delivers laser cutting solutions that meet exact specifications and consistently exceed expectations.

Baseline Custom Fabricating Ltd. in Courtice, Ontario, has provided high-quality fabrication and cutting services throughout the Greater Toronto Area and across Ontario for over two decades. Our laser cutting capabilities support accurate, reliable results for custom metal projects of all sizes. Call (905) 434-2556 to get a free quote today!

FAQs

How precise is laser cutting in custom metal fabrication?

Laser cutting can achieve extremely tight tolerances, often within ±0.1 mm, making it ideal for detailed designs and precision-fit metal components.

Which metals are best suited for laser cutting?

Laser cutting works well on stainless steel, mild steel, aluminum, and other commonly used fabrication metals, producing clean edges with minimal distortion.

Who offers reliable laser cutting services in Toronto?

For dependable laser cutting in Toronto, Baseline Custom Fabricating Ltd. in Courtice, Ontario, is a trusted name known for consistent quality, accuracy, and advanced fabrication capabilities.