FAQ: Understanding Laser Cutter Basics

The laser cutting process offers a range of benefits, acting as an integral part of the mocking-up and manufacturing of products by cutting and etching into a material. Laser cutters offer a diversity in utility from DIY fabrication for artists and hobbyists to large industrial-scale products designed for a specific purpose and require a higher caliber of precision. A relatively new technology initially introduced in the 1960s, laser cutters are slowly becoming ubiquitous as they are now starting to be used by schools, small businesses, and hobbyists alike.

Today we’re going to delve into laser cutting 101 by answering 3 frequently asked questions.

How Does a Laser Cutter Work?

- Laser cutters are known as a computer numerical controlled machine (CNC), meaning the machine is completely computer automated.

- Laser cutters use their laser to cut through a material. The laser comes from the laser resonator, which releases a single condensed beam of light that is then reflected through an arrangement of mirrors. The beam is then focused into an even thinner concentrated beam of light, which is then projected toward the material that will be cut.

What Types of Laser Cutters are There?

- There are 3 main types of lasers – each with varying cutting capabilities and material compatibilities.

- CO2 Lasers: CO2 lasers are the most common type of laser cutter. CO2 laser are known for their affordability, their lower usage of power, efficiency, and ability to cut through a large range of materials (wood, paper and cardboard, leather, acrylic, glass, a few plastics and foams).

- Neodymium Lasers: the laser is formulated from neodymium doped crystals which serve to minimize the overall wavelength, making them better suited to cut through thicker materials such as metals, plastics, and a few ceramics.

- Fiber Lasers: the laser is composed of a seed laser which is then intensified with special glass fibers. Fiber lasers offer a similar wavelength and intensity as neodymium lasers, making them also suitable to cut through thicker materials like metals and plastics.

How Do You Come Up with a Design that is Compatible with a Laser Cutter?

- In order to create a design that is compatible with a laser cutter, you must use software capable of supporting laser cutter drivers.

- For 2D designs you can use CorelDRAW, Adobe Illutsrator, AutoCAD, and Inkscape.

- For 3D designs you can use Solidworks, Autodesk Inventor, and Autodesk Fusion.

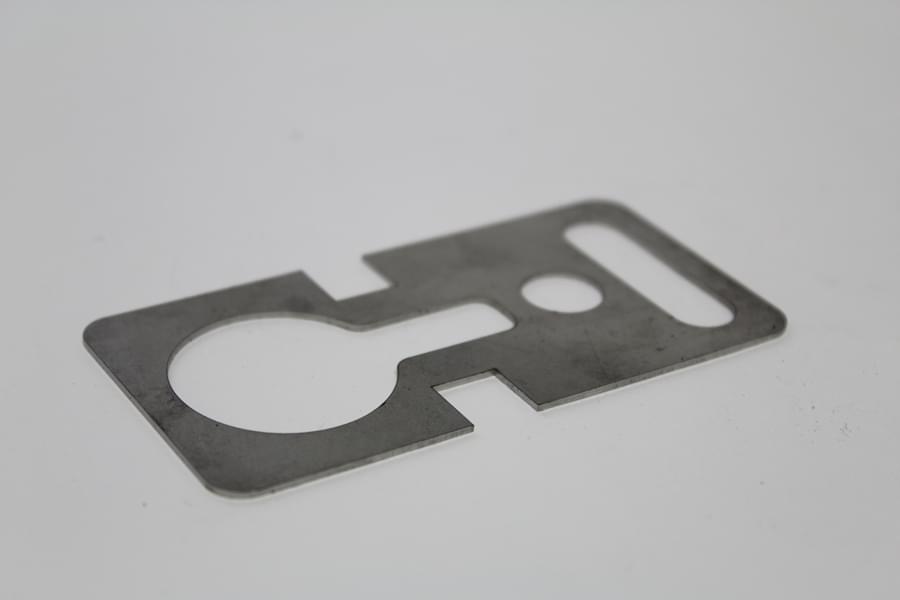

Baseline Custom Fabricating is Capable of Bringing Your Design to Life

If you’re unsure where to begin – start by calling a machine shop that offers laser cutting services. Luckily, Baseline Custom Fabrication is fully equipped with the knowledge and experience necessary to bring your unique design to life. Experienced in a range of industries including construction and manufacturing, our Fibermak Momentum Gen-2 3KW is capable of cutting materials with intense precision, yielding high-quality results every time. Our skilled technicians can assist you at every step to ensure that your design comes to life.